The government has announced that it aims to create a zero-carbon society by 2050, but the path to achieving this goal will be a rocky one. While the widespread use of renewable energy will be essential, there is disquiet about the ability of solar and wind power to provide a stable supply of electricity to support the Japanese economy, given that intermittency in supply will inevitably occur at times when they cannot generate power. It would be fair to say that thermal power generation is a practical option for making up for the intermittency. High-efficiency third-generation thermal power technology could hold one of the keys to bringing a zero-carbon future to fruition.

Special Feature 1 – The Zero Carbon Reality Third-generation thermal power technology is the trump card in reducing greenhouse gases

composition and photographs by Takakazu Kawasaki

“By 2050 Japan will aim to reduce greenhouse gas emissions to net-zero, that is, to realize a carbon-neutral, decarbonized society.”

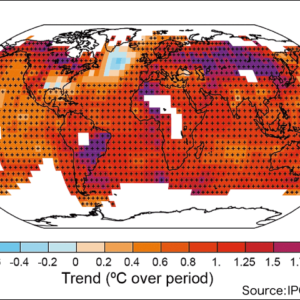

So declared Prime Minister Yoshihide Suga in his policy speech at an extraordinary session of the Diet October 2020. Then, at a meeting of the Global Warming Prevention Headquarters in April 2021, he announced that Japan will aim to reduce its greenhouse gas (GHG) emissions by 46% to approximately 790 million tons from FY2013 levels (1.48 billion tons) by FY2030. Initiatives aimed at creating a zero-carbon society are vital for the global environment, and numerical targets are inevitable, as each country around the world needs to strike a balance. The question is, how to scientifically achieve these targets.

- * Carbon-neutral: A situation in which the volume of emissions of CO2 and other greenhouse gases is reduced to zero when the volume absorbed by forests and the like is deducted.

Thermal power generation is essential

In Japan, 42% of emissions of CO2 —— which accounts for the bulk of GHGs —— came from power generation (FY2016, Ministry of the Environment data). I have been involved in research and construction of power plants within Japan and overseas for many years. The Institute of Industrial Science (IIS), University of Tokyo, where I work, is involved in research and development focused on such areas as ultra-high-efficiency power generation, advanced coal technologies, CO2 fixation, and renewable energy. Of these, ultra-high-efficiency power generation and advanced coal technologies —— which are among the research fields in which I specialize —— are technologies capable of making a substantial contribution to reducing CO2.

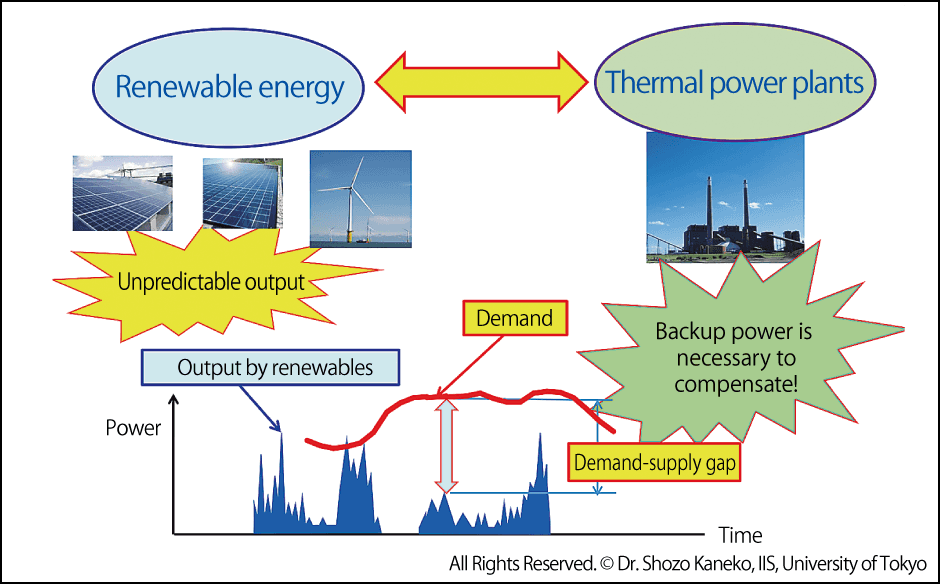

Many people may think that we simply need to switch all electricity to renewable energy. However, as there is intermittency in the generation of power from renewable sources, we face the major problem of how to make up for the deficiency. To get straight to the point, thermal power is essential if we wish to increase renewable energy use (Figure 1). Boosting the efficiency of thermal power generation is imperative in Japan in particular, given that the nation is dependent on imports for the majority of its energy resources.

Figure 1. Combination of renewable and thermal power generationPower from renewable energy fluctuates independently of demand, due to changes in natural conditions. Accordingly, backup power is essential to cover electricity demand.

In the case of solar photovoltaic power generation, electricity cannot be generated at night or on cloudy or rainy days. Wind turbines cannot generate electricity when the wind does not blow. Solar and wind power cannot always generate electricity when our society and lifestyle require it.

According to estimates by the Ministry of Economy, Trade and Industry (METI) and the New Energy and Industrial Technology Development Organization (NEDO), the capacity factor of renewable energy is 12–13% in the case of solar and 20–30% in the case of wind. Renewable energy facilities with a capacity of 1 million kW can be equated to one reactor at a nuclear power plant, but the actual electricity generated by these facilities per year would be just 120,000–130,000 kW in the case of solar and 200,000–300,000 kW in the case of wind.

There is another point concerning renewable energy that requires caution: almost all solar panels used for power generation are manufactured in China, while wind turbines are imported from Europe. As domestically produced equipment is basically not used, these facilities make hardly any contribution to the Japanese industry.

The low usage rate of electricity generated from renewable energy is a problem for countries other than Japan, as well. Described as an advanced country when it comes to renewable energy, Germany is famous for its wind farms in the North Sea. However, there is a 24 million kW (data for the period October 2011 to March 2012) gap between generation when the wind blows and when it does not. This equates to Kansai Electric Power Company’s total power consumption. The reality is that Germany imports electricity from neighboring countries when it does not have enough power.

Solar and wind power raise the issue of supply intermittency

Famously, industrial electricity charges in Germany are low. This is because the charges are kept low to guarantee the international competitiveness of German industry. On the other hand, Germany has some of the highest household electricity charges in the world, so German consumers bear the burden of industrial electricity charges.

Among the various kinds of renewable energy, hydroelectric power plants have been used in Japan for a long time. Some countries, such as Norway, generate as much as 700% of their domestic electricity demand using hydroelectric power. Norway exports electricity and has a per capita income almost 1.5 times higher than neighboring Sweden. Hydropower is the best kind of renewable energy. It also assists with soil conservation and flood control. However, Japan has few sites suitable for large-scale hydroelectric power plants, and construction is becoming complicated by the view that dam construction is a bad thing. While an increase in small and medium-sized hydropower plants is expected, these will be small in scale and few locations offer the right conditions, so construction costs will be high.

The biggest problem with solar photovoltaic and wind power generation is the aforementioned intermittency in supply. Storage batteries are thought to be one option for preventing such inconsistencies. However, storage batteries need to be charged, and their availability is just 50% at most, making them relatively expensive. Furthermore, it is very difficult in both technical and economic terms to build a storage battery with a capacity large enough to ensure the stabilization of lifeline utilities.

Solar farm in the town of Ainan, Ehime Prefecture.

Wind farm at Cape Soya in the city of Wakkanai, Hokkaido.

Let me explain what happens if a stable supply of electricity cannot be maintained.

On September 6, 2018, the Hokkaido Eastern Iburi earthquake (maximum seismic intensity: 7) triggered Japan’s first blackout (power outage) in Hokkaido. A blackout paralyzes most of society’s infrastructure. After the earthquake, it took 14 days to stabilize electricity supply and demand across Hokkaido. In January 2021, electricity usage in West Japan reached 99% of capacity, taking the region to the brink of a blackout.

Alternating current (AC) is used to supply electricity. The advantage of AC is that voltage transformation is easy, and increasing the voltage minimizes electricity transmission losses. Although controversy initially raged over whether AC or direct current (DC) should be used, the whole world now has an AC power grid made up of synchronous generators. AC requires a constant balance between power supply and consumption at any time. If demand for electricity is higher than supply, the frequency declines, whereas it increases if demand is lower. Japan uses two different frequencies, with electricity supplied at 50 Hz in East Japan and at 60 Hz in West Japan. The supply is adjusted to a very precise degree, within a range of ±0.2 Hz in Honshu (including Kyushu and Shikoku) and ±0.3 Hz in Hokkaido and Okinawa.

If the frequency drops by more than 1.5 Hz —— because, for instance, the power supply is unable to keep up with demand —— the turbines and generators at power plants will break, so power plants are fitted with a mechanism that triggers a circuit breaker called an Under Frequency Relay (UFR) to automatically cut the system off from the power grid. A situation in which one power plant after another is cut off from the power grid is called a blackout.

Japan has the world’s most stable power grid

The stability of Japan’s power grid frequency is world-class, and it is also top worldwide in terms of the low rate of outages. In particular, the ±0.2 Hz range is one of Japan’s greatest assets and the source of its international competitiveness. No matter where in the country you might be, you can use a stable supply of electricity for the same price.

For instance, Japanese cars are also produced overseas, but when Japanese cars fitted with engines manufactured in Japan are exported overseas, in some cases they fetch a higher price on the second-hand market than locally manufactured Japanese cars and may even be cheaper to insure.

Why are motor vehicles made in Japan so popular? The reason is connected to the precision of the engine parts. Engines consist of 10,000 components, and if the pitch of a screw, for example, is not uniform, it might become loose or even break. As Japan has a stable electricity supply, motors have a stable rotational frequency, and it is therefore possible to produce screws with a uniform pitch.

So how can Japan ensure a stable supply of the electricity required while increasing the use of renewable energy?

As stated above, the only solution is to use thermal power. Moreover, this will be thermal power generation using new, highly energy-efficient technologies. Put simply, even if we become carbon-neutral by 2050 and even if the running time of thermal power plants is reduced, the total capacity of thermal power plants will not be reduced. This is because power outages and blackouts will occur unless we have thermal power plants capable of quickly responding to electricity supply and demand.

In fact, even in Germany, although electric power companies have applied to scrap their thermal power plants, in some cases, the government has refused to grant permission, stating that the facilities should be left in place.

As thermal power plants need to be used effectively, the only option is to boost the amount of power generated by increasing generating efficiency to reduce fuel consumption. If generating efficiency improves, CO2 emissions will be reduced.

There is currently a lively debate around the idea of producing hydrogen or ammonia from renewable energy. Both hydrogen and ammonia are fuels. Whether we use these or fossil fuels, turning them into electricity requires the use of a boiler (steam turbine), gas turbine, or fuel cells.

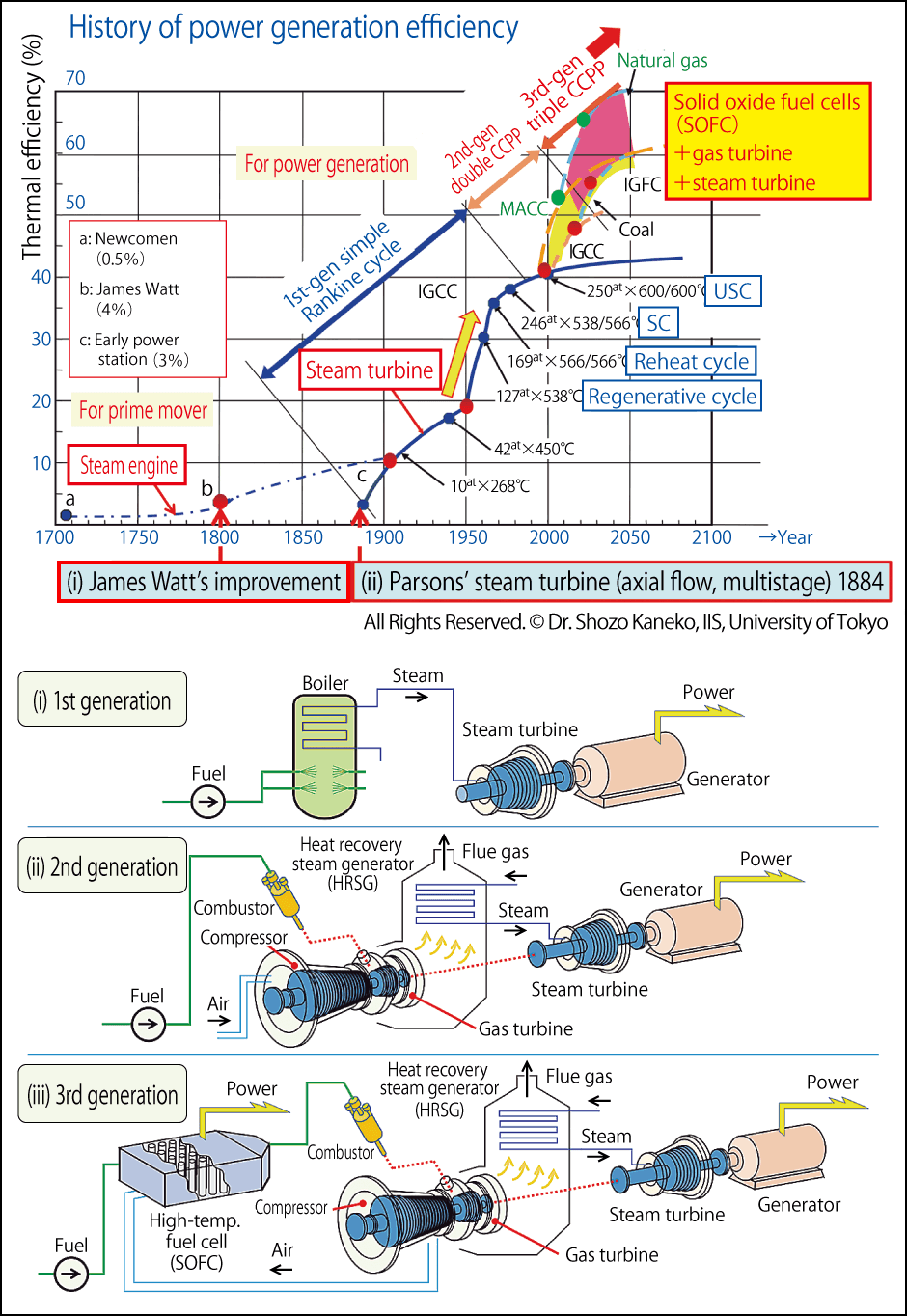

In the latter half of the 18th century, James Watt improved the reciprocating steam engine, which used thermal energy from steam, while Charles A. Parsons commercialized the rotating steam turbine in the latter half of the 19th century. First-generation simple cycle thermal power plants, which use steam turbines, initially had a generating efficiency of less than 10%, but efficiency improved after World War II and has now reached the 40% range in ultra-supercritical plants (USC) using steam at 600°C (Figure 2).

Figure 2. History of thermal efficiencyHigh-efficiency thermal power generation has been achieved through technological innovation after Watt improved the steam engine. The efficiency of first-generation simple cycle using a steam turbine ((i) in the lower half of the figure) is in the 40% range, while in the case of second-generation combined cycle (ii) it is 60%. Third-generation triple combined cycle (iii) makes it possible to achieve 70% efficiency.

The second-generation called double-combined cycle power plant (CCPP) now in widespread use employ both a steam turbine and a gas turbine. Natural gas combusted in compressed air drives the gas turbine to generate electricity, and the exhaust gas is used to make steam to generate more electricity by driving the steam turbine. The efficiency of double CCPP is around 55% in practice. While the gas turbine can use only gas or liquid fuel, solid fuel coal can be used if gasified. This is called Integrated Gasification Combined Cycle (IGCC) power generation. However, this represents the limit of generating efficiency in the case of double CCPP.

Possibilities for third-generation triple CCPP

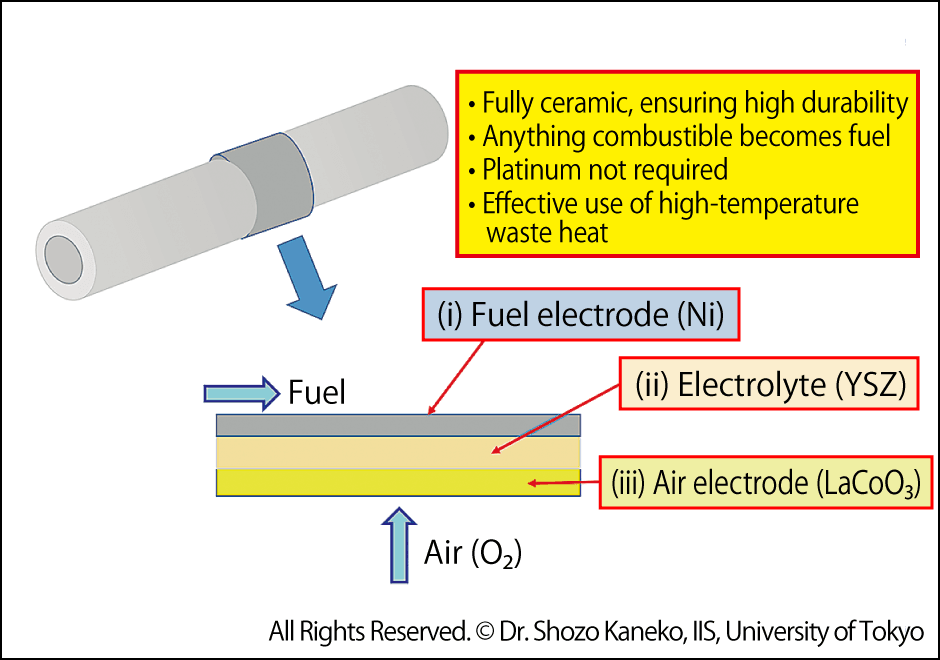

What I want to highlight is the third-generation triple CCPP by means of a system that combines high-temperature Solid Oxide Fuel Cells (SOFCs) with a steam turbine and a gas turbine. The thermal efficiency of power generation increases to around 70% when natural gas is used, but even gasified coal can achieve a figure in excess of 60%. As brown coal can also be used, this would enable Japan’s remaining coal reserves to be utilized (Figure 3).

Figure 3. Structure and advantages of SOFCs in thermal power generationSOFCs hold the key to third-generation triple CCPP. Unlike PEFCs used in FCV and the like, SOFCs can be combined with a gas turbine and steam turbine using waste heat at temperatures of 700–1,000°C for three-stage power generation. Using natural gas results in a generating efficiency of as much as 70%.

Japan is effectively the only country with this kind of fuel cell technology for thermal power generation, and coal gasification is also one of Japan’s unique technologies. Using these technologies would enable us to contribute to preserve the environment and further the industry not only in Japan, but across the globe.

Moreover, as SOFCs are ceramic and generate electricity using oxygen, pretty much anything combustible can be used as a fuel. The high operating temperature means that the waste heat can also drive the gas turbine and steam turbine. This three-stage power generation method enables energy to be used effectively.

In contrast, the hydrogen-based Polymer Electrolyte Fuel Cells (PEFCs) fitted in fuel cell vehicles and the like use platinum catalysts to generate electricity from pure hydrogen, which makes them expensive. Furthermore, electricity cannot be generated from their waste heat (80°C). SOFCs using yttria-stabilized zirconia (YSZ), on the other hand, permit high-efficiency power generation.

2 million SOFCs would be required for a power plant with a capacity of 500,000 kW, for example. As this implies mass production is necessary, capital investment in factories will be needed. The cost of cells decreases in inverse proportion to the production scale of the factory, but more than 100 billion yen of investment would be required to create a facility capable of mass-producing 2 million cells.

I believe it would be fair to say that Japan effectively succeeded in commercializing the industrial production of semiconductors, liquid crystals, solar panels, and lithium-ion batteries. However, because these are typically mass-produced goods, capital investment lagged behind China and South Korea and now the market has been captured by them. In my view, how we go about bringing to fruition the mass production of SOFCs will determine the future of Japan.