Demand for meat is surging, against the background of economic development and population growth in developing countries and emerging economies. As such, the world is expected to face protein supply shortages in the near future. However, increasing our existing dependence on livestock for the production of meat is an unrealistic option due to its environmental impact. Accordingly, scientists are conducting research and development aimed at obtaining new forms of protein that will transform conventional concepts, including cultured meat produced from the cultured cells of cows, pigs, chickens, and fish, meat alternatives that use protein from plants such as soybeans and algae, and even insect-based food.

Special Feature 1 – The New Era of Protein Resources New methods of obtaining protein will transform conventional concepts

composition by Rie Iizuka

The terms “cultured meat” and “meat alternatives” have come to be talked about as methods of producing “meat” that can serve as a substitute for conventional methods of obtaining protein resources.

Factors behind this include explosive population growth and the economic development of developing countries. According to a United Nations survey, the global population broke through the 8 billion barrier in November 2022, having risen from 7.875 billion in 2021. Estimates suggest that the figure will reach 9.7 billion by 2050, making the supply of food to feed the world’s surging population a major issue. In addition, demand for meat is growing as emerging economies become more affluent.

Increased cattle production is unrealistic

While one might think the answer would be to produce more meat from livestock, particularly beef, the fact is that this requires a great deal of resources. Japan’s Ministry of Agriculture, Forestry and Fisheries estimates that 11 kg of feed is required to produce 1 kg of beef. Maize is the principal form of feed, but it has a not inconsiderable impact on the environment, requiring a large quantity of water in its production. Moreover, the burps from cows, which are ruminants, contain a lot of methane. Said to have a greenhouse effect 25 times that of CO2, methane is a contributory factor in global warming. Accordingly, when thinking about the future, increasing cattle production to meet demand for meat is an unrealistic option.

At the same time, the issues of population growth and environmental impact are not the only perspectives driving the development of cultured meat and meat alternatives. First, animal welfare considerations create resistance to killing livestock. In addition, meat alternatives are gaining support in response to the growing number of those with vegan and vegetarian food preferences, as well as those with dietary restrictions due to their religion. Among the Millennials —— those born between 1980 and 1995, who grew up in the digital age —— the concepts of veganism, vegetarianism, and animal welfare are regarded as cool, and it is this generation that is driving support for cultured meat and meat alternatives.

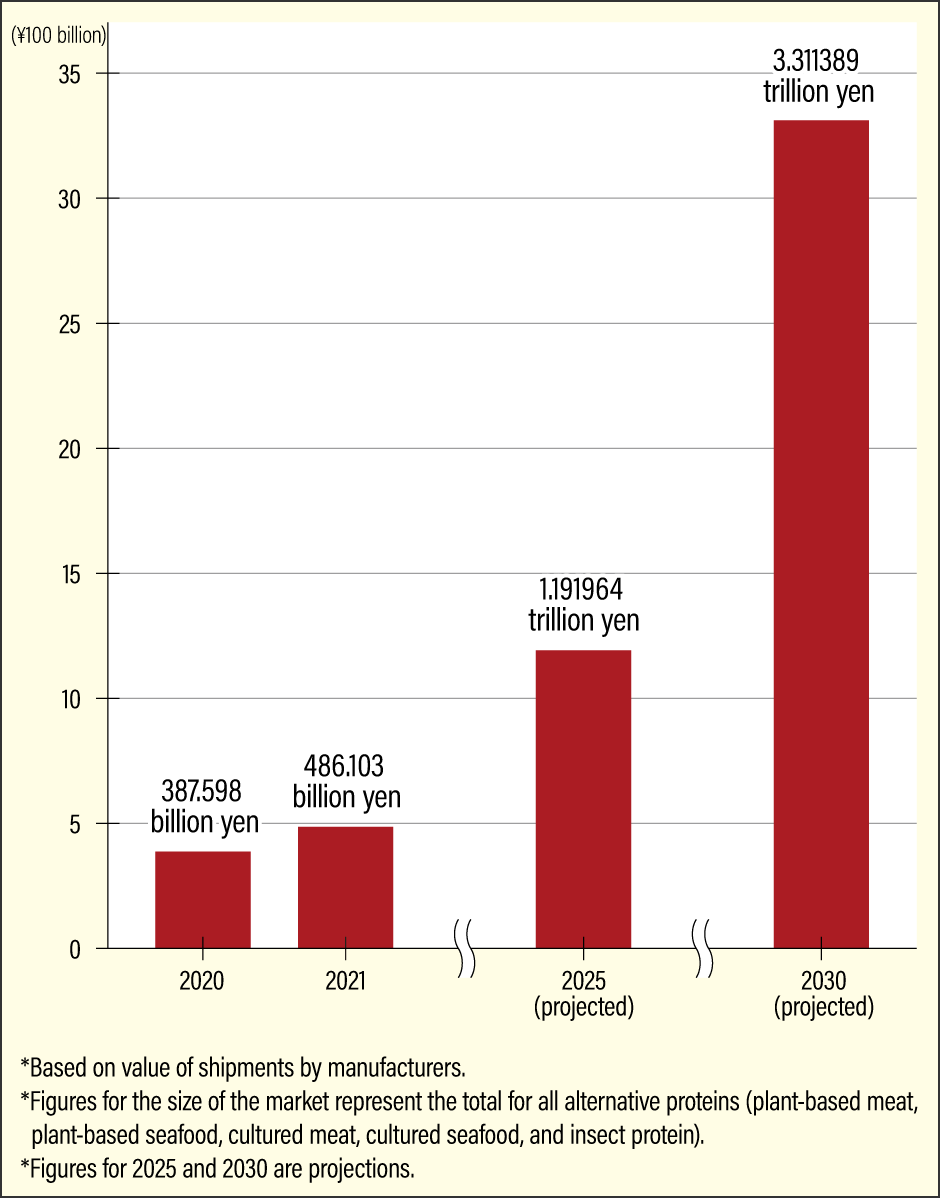

The combination of these social factors and personal preferences means the market for cultured meat and meat alternatives is thriving worldwide (Figure 1).

Survey by Yano Research Institute (2022)

Survey by Yano Research Institute (2022)

Figure 1. Forecast size of the global market for alternative proteinsWhile the main focus at present is plant-based alternative proteins, it is anticipated that the market will instantly see a major expansion once it becomes possible to sell cultured meat.

We are seeing progress in research and development focused on cultured meat, which involves culturing cells collected from target animals, such as cows and pigs. At the same time, one can already buy meat alternatives made by processing plant-derived protein —— principally from legumes —— to create something with the appearance of meat, insect-based foods, and meat alternatives involving protein made using fungi or microbial fermentation (Figure 2). Some forecasts suggest that the market in 2040 will see overall consumption divided between conventional meat, plant-derived meat alternatives, and cultured meat.

| Type | Overview | |

|---|---|---|

| Meat and seafood alternatives | Plant-based | Processed foods that replicate the flavor and texture of meat, using plant-based ingredients such as soybeans, peas, and mung beans. |

| Cell-based | Meat obtained by culturing cells obtained from such creatures as cows, pigs, chickens, fish, and shrimp. | |

| Dairy and egg substitutes | Plant-based | Processed foods made from plant-based ingredients that are created as alternatives to milk, dairy products, and egg products. |

| Cell-based | Milk and egg components produced using fermentation techniques, and milk and eggs produced artificially using cells. | |

| Insect-based foods | Insects | Processed foods and animal feed made from insect-based ingredients, such as crickets, horseflies, and houseflies. |

| Algae | Algae | Alternative proteins produced by growing algae or microalgae. |

| Other | Microorganisms and fungi | Alternative proteins produced using fungi or microbial fermentation. |

Figure 2. Types of alternative proteinsVarious techniques are being considered to address the shortage of protein resources.

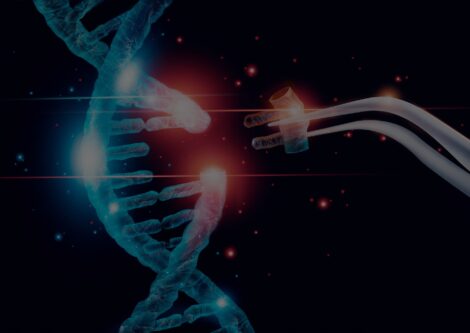

Cultured meat first appeared in 2013, when Professor Mark Post, a physiologist at Maastricht University in the Netherlands, produced a hamburger made from 20,000 cultured cow muscle fibers. Including research expenses, the cost of producing the 142 g hamburger was around 32.5 million yen, a fact that attracted a great deal of comment at the time.

Subsequently, university researchers founded numerous startups, primarily in the U.S. Cultured meat involves two technical challenges.

One is how to keep costs down when undertaking mass production. As well as a culture medium containing amino acids and vitamins, culturing the cells requires a growth factor that promotes cell proliferation and differentiation. Fetal bovine serum is used as a growth factor in the laboratory, but it is very expensive.

Solidifying is the other challenge in the cultured meat field

Various companies are competing furiously to develop a cheap growth factor. In Japan, there is a startup that has set a target of 20 yen per 100 g. The startup has developed its own cell culture system by using supernatant growth factor from culturing liver cells. It has succeeded in creating an environment similar to that found in animal bodies and in producing a growth factor within that environment.

In achieving mass production and greater efficiency, the question is how to keep the cost of culture media and nutrients down while manufacturing a large quantity of protein. Time will likely provide a solution to this problem.

Solidifying is the other challenge in the cultured meat field. Cells basically proliferate in a flat layer. However, the product needs to be thicker if it is to be enjoyed in the same way as meat.

The question of how to turn flat cells into something more voluminous is another area where companies demonstrate different approaches. Various methods and ideas are being explored, including turning cultured meat into something like cube steak by subjecting the cells to electrical stress, thereby creating an environment similar to resistance training; creating tubular cells and bundling them together to manufacture lumps of meat; or using mushroom hyphae as pillars to serve as a kind of scaffolding for the cells, so that they can grow thicker.

In a joint research project involving the University of Tokyo and a private sector company, researchers developed a new culturing method: cutting up cells using enzymes to separate them by eliminating the bonds between the cells, culturing them until there were around 100 million cells. They then mixed the cells with collagen, poured the mixture into molds, and cultured multiple rows of cells, creating an assembly of cells on a thin sheet with fibers all aligned in the same direction, and layered 40 of these sheets together to create a cultured cube steak around 1 cm square.

Aside from the technical issues, cultured meat has faced a barrier in the form of gaining approval in each country, as it is a completely new foodstuff. In most countries, not only is feeding it to others banned, but it is even prohibited for the researchers themselves to try it.

The only country where the commercial launch of cultured meat has been approved is Singapore, which has a low food self-sufficiency rate and is promoting efforts to bolster its food security. After the U.S., Israel is the country where research into cultured meat is flourishing the most, and people can sample cultured meat at an experimental facility operated by a cultured meat startup in central Tel Aviv. This cultured meat is available only as a sample and it has not yet been launched for sale.

Meat alternatives that do not taste like meat

However, in November 2022, the U.S. Food and Drug Administration (FDA) announced that it had okayed the safety conclusion in its first pre-market consultation of cultured meat made from animal cells, so the number of companies devoting their energies to development of such products will undoubtedly grow from here. Cultured meat is likely to reach the U.S. market sooner or later.

In Japan, after the Research Ethics Committee of the University of Tokyo granted approval in November 2021 for an experiment involving the sampling of cultured meat, the country’s first taste trial took place at the University of Tokyo in March 2022. Thus, sensory evaluation of taste and flavor is now possible in Japan, as well, representing a further step toward the development of cultured meat.

However, as various rules have yet to be established in Japan, it is likely to take some time before cultured meat becomes available in the shops. The sale of cultured meat will require rules to be established in international markets, including Japan.

Meat alternatives are another pillar of the new meat field. Unlike cultured meat, meat alternatives have already secured a certain share of the market, primarily in the U.S. (Figure 3).

Figure 3. Types of alternative proteins available on the market

When it comes to plant-derived protein, legumes are naturally the main raw material used. Most of what are referred to as meat alternatives are made from soybeans or peas.

One issue with meat alternatives is that, while they are presented as a substitute for meat, they do not actually taste like meat. However, the meat alternative launched by Impossible Foods, Inc. —— a company founded in 2011 by Stanford University professor emeritus Patrick Brown —— has achieved tremendous popularity in the U.S. The company ascertained that the tastiness of meat is affected by a compound called heme, which is found in hemoglobin and myoglobin. Accordingly, they collected a substance similar to hemoglobin from bacteria in legume root nodules, inserted it into yeast, and added the resultant pigment to the meat alternative, enabling them to manufacture a truly “meat-like” meat alternative. Many have said Impossible Foods’ product compares favorably with real meat and, as a major burger chain has begun selling it as a plant-based hamburger, even customers in Japan have the opportunity to try it.

Meat alternatives are also endorsed by people who cannot eat meat for religious reasons. For example, a number of meat alternatives have been designated as kosher (clean food), which means they are suitable to be eaten by followers of Judaism.

Japan is said to be lagging behind in the fields of cultured meat and meat alternatives, but there is an abundance of research into soybeans in our nation, as a country which has always had a culture of consuming them in a variety of forms, including tofu, miso, natto, and soy sauce.

In the U.S., most people think of soybeans as something that is pressed to get oil. The hulls left over after pressing soybeans for oil are rich in protein, but they have conventionally been regarded as feed for cattle and other livestock, rather than as human food. Thus, U.S. attitudes to soybeans differ considerably from Japanese perspectives.

A catalyst for the popularization of plant-based meat

In Japan, a major manufacturer of vegetable oil began researching soy meat as early as 1957, launching a product with a texture similar to meat in 1969. At that time, there was no concept of meat alternatives like we have today and virtually no market for a product of this kind, so the business languished in the red. Believing in the potential of soybeans nonetheless, the company kept the business going through to the present day, when meat alternatives are garnering attention as an idea whose time has come. The company’s orders for the product are reportedly 10 times what they were back then.

As one might expect, Japan has a treasure trove of highly niche technologies involving soybeans, and this company has developed more than 60 different types of granular soybean protein, in order to replicate the textural differences found in various types and cuts of meat.

The company also has an assortment of techniques for sorting soybean components and, by processing these components, it has even succeeded in creating a completely plant-based tonkotsu ramen. The dish replicates the original with quite a high level of precision, including a version of char siu pork from soybeans and soup made from emulsified soy milk. Technology of this kind is probably beyond the reach of companies overseas. It is the result of long years of research into soy protein.

Another company from Japan uses whole soybeans —— rather than the defatted soybeans from which oil has been extracted —— to manufacture a meat alternative. Using whole soybeans helps to eliminate the distinctive odor of defatted soybeans. The company is meticulous even about the variety of the soybeans it sources, taking care to use beans high in oleic acid, and also ensures they germinate before use. It would be fair to say that this is a meat alternative that could only be created in a country like Japan, which knows all there is to know about soybeans.

It is a pity that the U.S. is the leader in the field of soybean-based meat alternatives, despite Japan having this environment. A crucial challenge for the meat alternatives manufactured by U.S. companies is getting close to the flavor and texture of animal meat. The key thing is the need to reach a level at which people who had been in the habit of eating conventional meat feel that plant-based meat is a tolerable alternative. That would appear to have been a catalyst for the popularization of the plant-based meat created by the aforementioned startup.

Perhaps precisely because we already eat soybeans in Japan, people here in fact might not feel there is any need for alternatives to animal protein. I myself am often asked whether there is any meaning in going out of our way to eat plant-based meat, when we already have tofu and natto in Japan.

In fact, it is not just meat-eating that is on the rise worldwide; so, too, is the consumption of fish, due in part to the growing popularity of sushi. Many fish species are already on the verge of overfishing, with farmed fish more common than wild in the case of some species. Accordingly, work to develop cultured seafood and seafood alternatives is also underway.

Other alternative proteins include algae, euglena, and insect-based foods.

Allow me to deviate briefly from the topic of new protein sources. There is currently a boom in research aimed at harnessing the power of technology to produce all kinds of foodstuffs. Plant-based egg substitutes are already being produced, while some companies have started developing cultured cow’s milk and even breast milk alternatives, based on elaborate analysis of the components of breast milk.

Once cultured meats and meat alternatives become widespread, we could well see a larger number of options in supermarkets, with labels such as “natural meat,” “cultured meat,” “meat alternatives (soybeans),” and “meat alternatives (algae)” lining the shelves, and the very concept of meat itself could change.

Some years before becoming British prime minister, in a 1931 speech entitled “Fifty Years Hence,” Winston Churchill predicted, “We shall escape the absurdity of growing a whole chicken in order to eat the breast or wing, by growing these parts separately under a suitable medium.” While the timing of his prediction might have been off by several decades, we now have the technology that Churchill foretold.

The development of cultured meat and meat alternative technologies seen to date is part of a new technological system called foodtech. Foodtech is hard to define, as it is a new concept, but to me, the term refers to new food technologies as a whole, encompassing the entire food system of production, processing, distribution, and consumption. New things are about to appear in every part of that system, giving rise to a diverse food landscape.