Plastics made from petrochemicals generate CO2 in their manufacture and incineration. They also cause various environmental problems because they do not readily decompose in the natural environment. In addition to concerns about their impact on marine organisms and ecosystems, there are fears about their effects on humans via the food chain. However, given that plastics are indispensable in our daily lives, eradicating them is impossible. It goes without saying that we need to reduce their use, so there is a pressing need to develop plastic alternatives that minimize the burden on the environment.

Special Feature 1 – The Zero Carbon Reality Developing plastic alternatives that do not burden the environment

composition by Toshiko Mogi

In the latter half of the 20th century, quite a few researchers began to sound the alarm about the plethora of plastic goods in our lives, triggered by such issues as the depletion of petroleum resources and questions around waste management. However, most global citizens failed to listen to them. The tide only turned in the 21st century.

More than half are disposed of by high-temperature incineration

One catalyst for this change appears to have been a video featured in media reports in 2015. A team of researchers conducting a study off the coast of the Central American country of Costa Rica rescued a sea turtle they had found with a plastic straw stuck up its nose. Moved by these images, many people began to take an interest in the problem of marine pollution by plastic waste. Furthermore, the discovery of plastic products in the bodies of marine organisms such as seabirds and sea turtles fueled concern about the impact on not only marine wildlife and ecosystems, but also humans via the food chain, highlighting the issue as one that needs to be resolved.

While we talk about “plastic,” the term encompasses a diverse array of different substances. The difficulty in separating them for collection and recycling them arises because materials and additives with different properties are used in the manufacturing process. Currently, more than half of all used plastic products in Japan are disposed of by means of high-temperature incineration and the CO2 emitted causes global warming.

Accordingly, in the case of single-use plastics—the type of plastic waste with an especially high likelihood of being discharged into the ocean—the solution is to reduce the amount of plastic we use and to develop plastic alternatives that lessen the burden on the environment if they should end up in the sea.

The prevailing approaches to replacing plastics can be broadly divided into two categories. The first involves abandoning plastics completely and using something else. Examples such as switching from plastic straws to paper ones to reduce the environmental burden fall into this category. The second involves making plastic goods from different materials. My research focuses on this area. The fundamental idea that inspires my research is that we should seek to exist in harmony with plastics, rather than abandoning plastic goods wholesale as products harmful to the environment.

Reducing the use of plastic products has now become a major challenge in Japan, where a charge for plastic shopping bags was introduced last year. On the other hand, the COVID-19 pandemic that began last year has actually increased the quantity of disposable plastic goods consumed in daily life, due to a rise in the use of such items as food containers and packaging materials for meal takeout and delivery, and the nonwoven fabric masks that are essential to prevent infection.

Use of the word “fabric” in the term “nonwoven fabric mask” gives rise to misconceptions, as these masks are actually made of plastic. The transparent acrylic sheets and screens installed at cash registers and in restaurants are also plastic products, as are the protective disposable gowns and face shields used in medical settings.

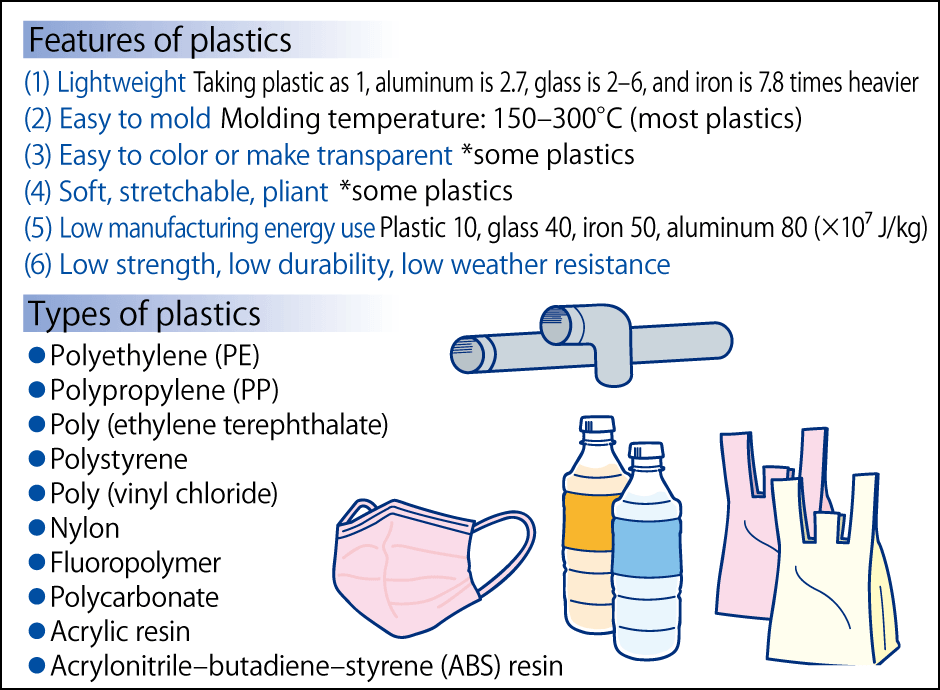

The many benefits of plastics have made them a popular choice, enriching our lives and making them more convenient. These advantages include their low price, light weight, robustness, and resistance to decay, as well as their ready moldability, which opens up a versatile range of design choices (Figure 1). However, these properties of robustness and resistance to decay bring with them the disadvantage that plastics do not readily decompose in the natural environment, leading to environmental problems.

Figure 1. Features and types of plasticsA wide variety of plastics are used for a diverse range of purposes in our daily lives, including shopping bags, Poly (ethylene terephthalate) plastic bottles, nonwoven fabric masks, and polyvinyl chloride pipes.

So, what should we do to ensure we can continue using the plastics we need for daily life without imposing a burden on the environment? I believe we need to replace the plastics we have right now with plastics that do not create an environmental burden. This means developing new plastics that decompose in the natural environment, while retaining the convenience of the plastics used in everyday life. And that means coexistence with plastics, which is the basis of my research.

Biodegradable alternative materials

Biodegradability is the essential property required of plastics to enable us to coexist with them. Biodegradability means decomposition to the molecular level by means of the action of microorganisms after use, ultimately aiming to reach a state in which they are returned into the natural environment in the form of CO2 and water. Plastics derived from petroleum are not biodegradable. Neither are biomass alternatives to petroleum-based materials. Even if we switch to using biomass-based materials, we cannot solve the problem of post-use plastic waste unless they are biodegradable.

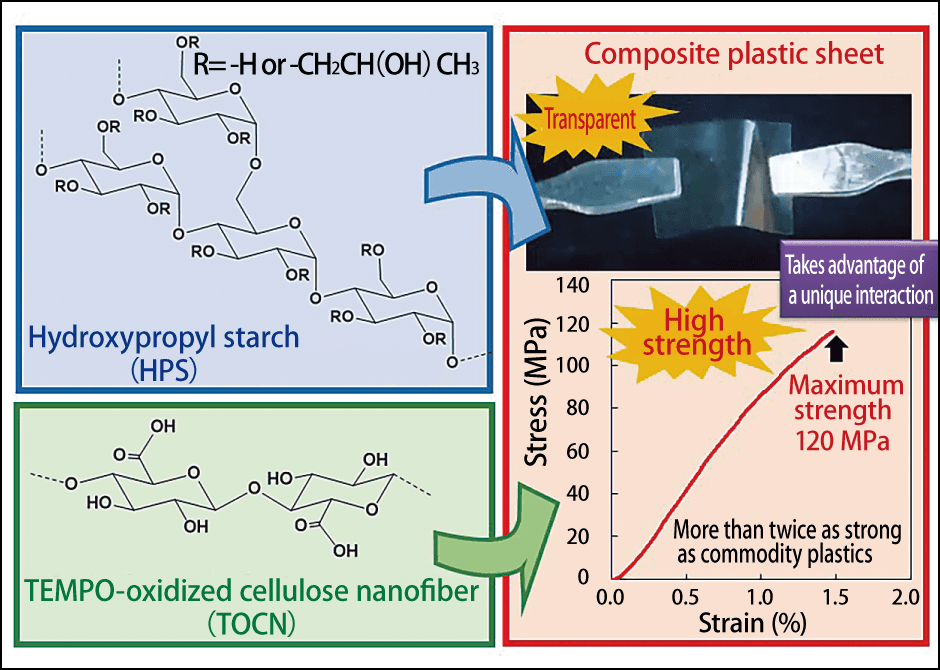

There is a particular need for us to switch to marine biodegradable plastics, which impose little burden on the environment even if discharged into the ocean. In March 2020, my research team at Osaka University published the results of a joint research project with a company that has an established reputation for its modified starch technology, in which we successfully developed a marine-biodegradable plastic sheet (Figure 2). Made from cheap and readily available materials in the form of starch and cellulose, the plastic sheet we developed is waterproof and more than twice as strong as conventional plastic goods. Its most notable feature is its marine biodegradability.

Figure 2. Strong, transparent starch-cellulose composite sheetA composite of hydroxypropyl starch (a modified starch for industrial use) and cellulose nanofibers (a new material with a diameter of 10 nm) was used to create a new marine-biodegradable material.

The marine-biodegradable plastics developed hitherto in Japan are classified as aliphatic polyesters. They are not only inferior in quality to the conventional plastics polyethylene and polypropylene, but also more than twice as expensive and can only be manufactured in small amounts. They will not enter widespread use in society unless these issues are resolved.

Accordingly, we focused on alternative materials in the form of biomass resources, which are cheap and available across the globe in large quantities. Starch is the principal component of carbohydrates and found in abundance in corn and potatoes, while cellulose is the principal component of plants. Both are therefore cheap, easily accessible materials.

However, starch has a weak point when it comes to water resistance. Products that dissolve (collapse) before use cannot be brought to market. To overcome this drawback, we combined the starch with cellulose nanofibers derived from wood pulp to form a composite. Cellulose nanofibers are very thin fibers with a diameter of just a few nanometers (a nanometer is one-billionth of a meter), equivalent to one ten-thousandth the diameter of the pulp fibers. Not only did this substantially increase the water resistance of the starch due to the strong interaction between the polysaccharides, but it also resulted in a transparent plastic sheet more than twice as strong as existing products of the same thickness.

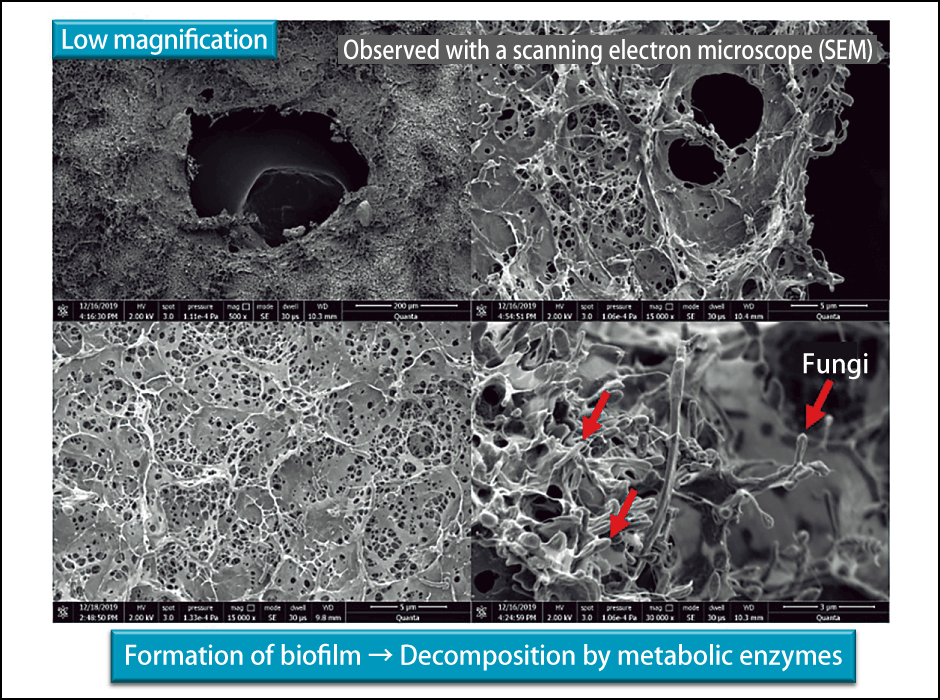

As microorganisms are required for its decomposition, the sheet is resistant to ordinary forms of water, such as rain. However, decomposition proceeds when the sheet is immersed in seawater for a month. In an experiment, we found that the sheet developed holes, around which many microorganisms marine fungi (Figure 3). This suggests that a biofilm formed on the surface of the sheet and that the sheet had been biodegraded by enzymes metabolized from the biofilm.

Figure 3. Marine biodegradability of the composite sheetWhen the sheet made from a composite of starch and cellulose was immersed in seawater for a month, decomposition progressed and the sheet developed holes, around which many fungi were observed to have gathered.

If the product of this research can be commercialized, the use of cheap, abundantly available starch and cellulose will help to reduce CO2 and substantially contribute to solving the problem of ocean plastic pollution. While there are still issues to be resolved, such as the hydrophobicity (ability to repel water) of the part in contact with food, we are aiming to put the sheet into commercial use in food packaging by 2025.

Being green is not enough to achieve commercial success

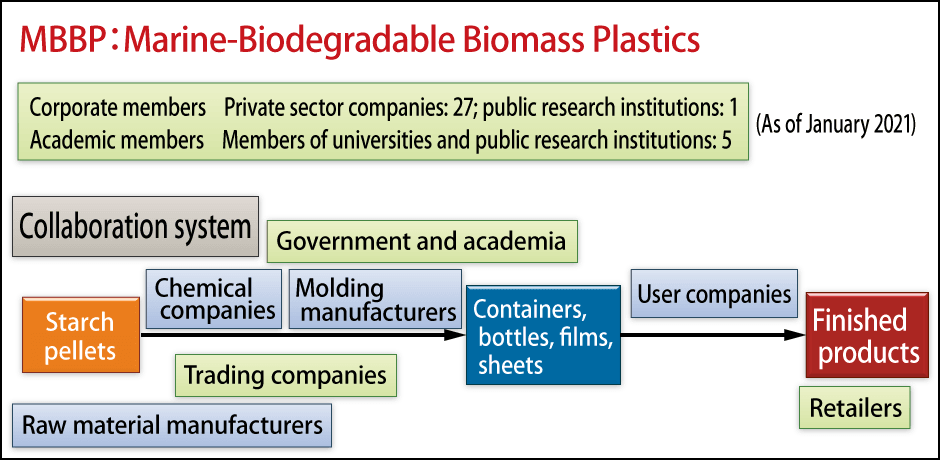

The applications and take-up of the marine-biodegradable plastics launched on the market to date have been limited. Achieving the development and widespread use of marine-biodegradable plastics that can coexist with our planet requires such plastics both to have properties enabling their use in the same way as existing plastics and to be competitive in terms of price. Accordingly, in September 2020, my laboratory established a platform for partnerships involving industry, academia, and government, with the objective of developing and commercializing marine-biodegradable plastics and ensuring their widespread adoption in society (Figure 4). This is because we believe that strong partnerships between industry, academia, and government are essential to address the challenges of commercialization and popularization.

Figure 4. Establishment of the MBBP Development Platform (September 2020)The platform aims to promote the widespread adoption by society of the results of development efforts through partnerships between a diverse array of players in industrial fields involved with plastic goods, including manufacturers of raw materials, chemicals, and molded goods, corporate customers, and retailers.

MBBP website http://www.chem.eng.osaka-u.ac.jp/mbbp/

The platform is called the MBBP (Marine-Biodegradable Biomass Plastics) Development Platform.

Its members include leading private sector companies in various specialist fields, manufacturers and users of plastic products, and universities and public research institutions.

The catalyst for drawing up this vision was our experience 11 years ago of bringing to market a roof paint made with vegetable oil, in partnership with an Osaka paint manufacturer.

Even if a new material with a lower environmental burden is developed, there can be several reasons why the market for it might not expand, including its higher cost compared to existing plastics and lacking the same properties and functions. Products do not become commercially successful solely on the basis of being green or environmentally friendly.

The roof paint made from vegetable oil we launched in partnership with a paint company was not only eco-friendly, but also offered outstanding performance in such areas as the enhanced weather resistance achieved by tapping into the distinctive characteristics of the vegetable oil. Gratifyingly, it continues to sell reasonably well even now, which means the results of our research are helping to reduce greenhouse gases.

During the transition from development to commercialization, I realized how many companies are using plastic products. Take the retort pouches used for curry and other foods, for example. While the exterior is made of white plastic, the inner surface that comes into contact with the food is made of an aluminum-based material. Look at milk cartons, too. The outside is paper, but the inside is coated with plastic to ensure that the liquid does not leak out.

Petroleum is refined into naphtha, and low molecular weight compounds obtained by means of naphtha cracking are polymerized to produce plastics, which are high molecular weight compounds. These are then pelletized and molded and processed for a wide range of applications. Companies with specialist technologies are involved at every stage in the process. It is thanks to such invisible partnerships that user-friendly plastic goods have been produced cheaply and in large quantities.

For marine-biodegradable plastics, as a late entrant to the market, to achieve victory over existing plastics in market competition and to become widely used in our daily lives, it is necessary to quickly develop molding and processing technologies suited to the properties of marine-biodegradable plastics. We hope that the partnerships created via the platform will assist in swiftly achieving this.

So far, I have discussed the development side, but before closing, I will also touch upon the use of plastics.

No matter how outstanding the plastic alternatives developed might be, they are nothing more than pie in the sky unless consumers actually choose to use them. And even if consumers opt for these products, they too will end up imposing a burden on the natural environment if they are simply left in the wild without being properly channeled into waste collection routes after use.

Coexistence with plastics and society

While some people see the issue of waste as merely a question of etiquette, I do not agree. I believe that what is needed to ensure that we can continue using plastics is not only to switch from existing plastics to those capable of coexisting with our planet, but also to ensure that consumers learn about plastics and think about what type of plastic products they should choose, how to use plastics, and how to dispose of or recycle them after use.

Based on my belief that it is important to teach the public about the importance of plastics, rather than demonizing them, I actively engage in furthering a proper understanding of plastics, including the problem of plastic waste among the public. I hold public lectures that anyone can attend and have set up a website as a forum for thinking about coexistence with plastics. In addition, I make a point of conducting on-demand workshops for junior and senior high school students, who will lead the next generation.

It is not only consumers who use plastics. Companies, too, use plastics in the containers and packaging of their products, for example. However good for our health or environmentally friendly the products developed, manufactured, and sold by companies, they cannot achieve coexistence with the environment if existing plastics that burden the environment are used for their containers or packaging.

I believe having companies that use such plastics take the lead in developing and selling products capable of coexisting with the environment will ensure that companies and the public act in tandem to take a great step forward in achieving coexistence with plastics. I hope companies that use plastics will also participate in the MBBP Development Platform and I plan to distribute information to encourage this development.

The success or failure of plastic alternatives that will shape the future of our planet lies in the hands of each and every one of us as global citizens. Let’s create a sustainable future for people and the earth alike.